Manufacturing Process and Plant

Our factories are an antenna receiving and emitting the knowledge existing all over the world.

Our manufacturing process is based on the Rhizome model, each factory is capable of testing, certifying and implementing any new technology or science that will help the construction and the community thrive.

Always abiding to criteria that put Human, Earth and the economy at the same level of importance.

Project Summary

The housing crisis is a deep and complex problem. Not only is this a problem in our country, but the entire world also needs a new, disruptive technology and business model. Current solutions are failing, and one cannot simply rely on the Government to ease the costs of construction by building “low-income housing”. Ultimately, these current strategies will continue to perpetuate newer ghettos that are not sustainable.

Our new vertically integrated business model and state-of-the-art technological factory will completely change the world of construction and real estate

A brand-new manufacturing process is the Future!

We are bringing five important changes:

-

- Our Factories must be local or within a 100-mile radius of the development territory, because real estate is a local problem.

- The Factory is automated primarily to reduce the time of construction, making the amount of labor minimal. It also guarantees quality control that cannot be achieved by human. This further eliminates the rudimentary permit process, make every construction development an “appliance”.

- Our Factory can build ALL development types of the Developer’s wishes (Schools, Hospitals, Resorts, Hotels, warehouses, etc.).

- The construction is based on three materials that cover 80% of the construction and are recycled, local and cheap:

- Structural

- Insulation

- Finish products (sinks, tubs, tiles, counters, flooring, roofing etc.).

- Our Factories will be self-contained and have all the necessary licenses for a traditional Type I construction permit.

- All Licenses owned by the factory include Engineer, Architectural and Contractors licenses.

- It is a One Stop Shop for every part of the construction process:

- Entitlements, permits and calculations

- Total Construction (off site and onsite, from foundations to roofing). We call this TURNKEY SMART DEVELOPMENT (TSD). So smart, that every building or structure has strategic sensors to detect and monitor every aspect of the technology. Imagine a plumbing leak that is detected by a sensor right before damage or issues arise. The sensors detect and sends messages or schedules the maintenance depending on the severity of the issue. Data from those sensors will be sent to the factory that built it, to further optimize performance.

- Lastly, the Factory does NOT sell. It is not a customer-based business. It is a Tool that will entitle, build, and manage every project for the Developer. It is a 501c3 (Non-profit) Company/Factory/Developers Tool, that builds EVERYTHING AT COST FOR THE DEVELOPER!

- Changing the PROFIT Process:

- Today, a Developer must forecast the profits all the intermediaries in the industry before he can make his own profit. This is already a problem in the traditional

business world (stocks, storage, commodities). In the Real Estate business, where development time is lengthy, and the projects value is based on a globalization, a developer can go out of business with a single project! This is especially true when a Developer has already paid everyone, and has gone through all the normal obstacles, before even completing his development project. Additionally, at the moment the developer is ready to sell their building, the economy may have been altered by unforeseen, devaluing their project less than the costs incurred to build. - By putting all the licenses under the Factory “umbrella” the Developer can build his/her buildings or projects at fair market cost. Consequently, without having

to pay the profits to outside entities, such as architects, engineers and contractors, the combined savings average 40% of the entire cost of the construction project. - This is a disruptive approach and will forever change the course of building for the Future World! It’s also the core of our business model and the solution to the National Housing Crisis! You can cut back the construction cost by 60% globally and achieve astounding profits and astonishing finished products

The Future of Construction & Manufacturing

In today’s globalized, competitive marketplace, being able to leverage technology to deliver faster turnaround times, meet lower pricing goals, provide customizable options, and deliver optimal quality can mean the difference between sustainability and irrelevancy. In this document, we will explore some of the leading solutions GloGreen Global LLC transforms the construction & manufacturing industry:

- Automation for cost savings

- Computer Numerical Controls for improved productivity

- Smart data for quality assurance

- Closed loop system for efficiency

- Connectivity for safety and communication

- Security solutions to protect it all

- Possibility to implement new technologies and knowledge

- Because the core of material is always the same, structural (steel of shipping container), insulation (UHPCC), finishes (UHPNC); our system of construction is completely vertically integrated including design, entitlement and permit process and construction

- Every factory will also include all licenses necessary for construction (architect, engineering, contractor and any trade necessary)

- Therefore, the owner of the factory has to be a developer eliminating the profit of all other trades needed for construction (up to 40% saving just here).

- The entire process is defined by a proprietary BIM software that from the design, the architect creates a cascade of tasks that start from the architect and engineer and goes to every department without any human involvement

- Within our manufacturing facility, our production capabilities are determined through logistical analysis of robotic equipment performance, transportation factors, human capital and role requirements, material procurement, storage and other time and resource sensitive conditions

- The calculations in this document are per the design of our Decatur Hotel in Las Vegas, NV

- The hotel provides us with key details to support the manufacturing facility design and operating strategy

- The factory is a tool for the community. Human resources, relationship with the authority, and material sourcing found as much as possible within the territory

- The primary production benefit comes from our automated shipping container fabrication

- The robotic arms used for cutting, reinforcement welding, insulation, painting etc. can complete specific work orders (modification of one shipping container) in approximately two hours.

- With four robotic arms in the facility, we conservatively will produce 40 container work orders per 24 hour

Decatur Luxury Extended-Stay

All our studies and calculations within this presentation are based on our Decatur Hotel in Las Vegas, which is a luxury extended stay hotel.

Refer to the presentation “Building technique” for the architectural and engineering details discussing our technology.

Building Specs:

- 137,000 ft2 total with 20,000 ft2 floor plan

- 7 stories (including mechanical floor and roof penthouses)

- 129 one-bedroom units (600 ft2)

- 4 penthouse units (1,200 ft2)

- 10 laundry rooms

- 4 community amenity spaces (600 ft2)

- Rooftop swimming pool

- Total shipping containers used: 403

Factory Building Layout

- 1,086 shipping containers

- 5-story + 1 subterranean (possible)

- White container dimensions are 40’x8’x9.6’

- Orange container dimensions are 20’x8’x9.6’

Manufacturing Machinery

Machinery:

- Lift systems

- Robotic machining with interchanging tools capable of cutting, welding, painting, installing

- Articulated robots

- SCARA (selective compliance assembly robot arm)

- Cartesian robots

- Delta robots

- Rail system

- 6-axis CNC machine (Click to view video)

- 3D Printer

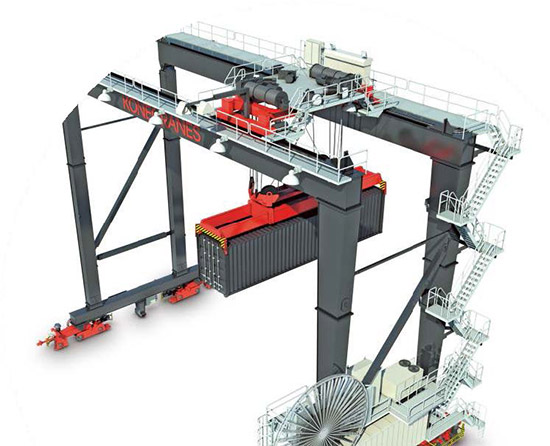

- Gantry crane

Reinforcement Sub-sections

1. Reinforcement: Due to automation manufacturing logistics will occur on a 24- hour basis

- Deliveries of steel supports

- Steel prep according to specifications CNC machines to modify steel per specifications

- Steel reinforcement installation to container

- Transport of completed reinforcements to ‘Main Section’

- Storage space for extra stock (leftover container sections and conventional steel)

Decatur Structural Reinforcement Production & Duration:

- Preparation of HSS supports per design spec (22 ft/container)

o 150 hrs or 7 days - Preparation of bottom/top side rail supports per design spec (60 ft/container)

o 150 hrs or 7 days - Initial welding prior to installment in container

o 600 hrs or 25 days - Custom fixture fabrication (200 units)

o 100 hrs or 5 days - Group all supports/fixtures for work order (403 work orders)

o 200 hrs or 9 days

- Total Required Preparation Time

- 1,200 hrs or 53 days

- Avg Preparation Time/Container

- 1,200 hrs ÷ 403 containers = 3 hrs/container

Electrical Sub-sections

2. Electrical: Due to automation manufacturing logistics will occur on a 24-hour basis

- Deliveries of electrical materials, lighting, appliances, etc.

- Quality control and sorting

- Preparation of fixtures for all necessary equipment for work order

- Depending on design specifications appliances (TV’s, refrigerators, dishwashers, etc.) will be procured as needed and installed on site

- Storage space for extra stock

Decatur Electrical Preparation Production & Duration:

- Preparation of wiring (4,500 ft)

o 100 hrs or 5 days - Preparation of electrical infrastructure (4,500 ft)

o 100 hrs or 5 days - Installation of LED lighting strips and fixtures (9,000 ft)

o 120 hrs or 5 days - Installation of switches/dimmers (300 units)

o 80 hrs or 4 days - Installation of sockets/outlets (1,500 units)

o 80 hrs or 4 days - Installation of appliances (1,800 units)

o 120 hrs or 5 days

- Total Required Preparation Time

- 600 hrs or 28 days

- Avg Preparation Time/ Container

- 600 hrs ÷ 403 containers = 1.5 hrs/container

Coordination will occur with Papercrete production along with ‘Non-Structural Architectural Design Elements Section’ for any custom elements that are built around electrical appliances.

Plumbing Sub-sections

3. Plumbing: Due to automation manufacturing logistics will occur on a 24- hour basis

- Delivery of pipes, fittings, fixtures, valves, pumps, etc.

- Quality control and sorting

- Preparation of fixtures for all necessary equipment for work order

- Storage space for extra stock

Decatur Plumbing Preparation Production & Duration:

- Preparation of high-pressure piping

o 100 hrs or 5 days - Preparation of drain piping

o 150 hrs or 7 days - Installation of fixtures

o 120 hrs or 5 days - Comissioning & testing

o 80 hrs or 4 days

- Total Required Preparation Time

- 450 hrs or 21 days

- Avg Preparation Time/ Container

- 450 hrs ÷ 403 containers = 1.2 hrs

Coordination will occur with Papercrete production along with ‘Non-Structural Architectural Design Elements Section’ for any custom elements (toilets, faucets, tubs) that will require plumbing fixtures.

Sheet Metal and HVAC Production

Mechanical Sub-sections

4. HVAC: Due to automation manufacturing logistics will occur on a 24-hour basis

- Deliveries of fans, coils, dampers, duct materials, etc.

- Quality control and sorting

- Ductwork fabrication

- Installation & assembly of ‘terminal units’

- Storage space for extra stock

Will collaborate with ‘Papercrete Section’ to design blocks that house the supply and exhaust registers and install fixtures to hold ductwork and HVAC components in place in sidewall.

Ductwork Fabrication Production Production & Duration:

- Branch ducts (supply and exhaust)

o 13,000 ft - Principle ducts (supply and exhaust)

o 5,000 ft

Total Required Length: 18,000 ft

Avg Length/ Container: 45 ft - Grille installation (10 min)

o 1250 units = 210 hrs or 9 days - Damper installation (15 min)

o 300 units = 75 hrs or 4 days - Duct transition connections (5 min)

o 800 units = 70 hrs or 3 days - Duct elbow connections (5 min)

o 250 units = 21 hrs or 1 day - Terminal heating/cooling unit (30 min)

o 140 units = 70 hrs or 3 days

- Total Required Assembly Time

- 450 hrs or 20 days

- Avg Assembly Time/ Container

- 450 hrs ÷ 403 containers = 1.2 hrs

Papercrete UHPCC Insulation Blocks Production

- Measurement of materials (paper, water, cement, sand, etc)

- Blending of Paper

- Mixing of materials

- Pouring into forms to create blocks

- Rack system allowing options of outdoor curing, or oven curing depending on climate

- Organizing/grouping blocks necessary to complete work order

- Directions for proper assembly of papercrete blocks in container

Note: This department capable of working in congruence with sub-sections of ‘Shipping Container Modification Section’ to prepare specific blocks for assembly (Some blocks serve as housing/supports for HVAC, electrical, and plumbing components). Components may be transferred from respective sub-section to the ‘Papercrete Section’ so that papercrete can be poured around the components.

UHPCC Production Capability:

- Approximately 5,000 blocks/day of UHPCC (papercrete) can be produced

o Total volume of 160 yd3 of UHPCC per day.

Decatur Building UHPCC Requirements:

- Hotel rooms (3” thickness)

o 120,000 ft2 = 1,120 yd3 - Penthouses (3” thickness)

o 5,600 ft2 = 52 yd3 - Corridors/stairwells (3” thickness)

o 32,000 ft2 = 300 yd3 - Mechanical room (3” thickness)

o 10,000 ft2 = 92 yd3

Total Required Volume = 1,550 yd3

Avg Volume/Container = 3.88 yd3

With an average required production rate of 3.88 yd3 of UHPCC per container designed for 40 container work orders each day, we are capable of producing 160 yd3 of UHPCC each day. All UHPCC blocks are the same shape, have sufficient storage/curing space within our manufacturing facility and will not impede construction.

CUSTOM ARCHITECTURAL UHPNC ELEMENTS PRODUCTION

- Convert design to program for CNC or 3D printer to make initial model

- Thermo/Vacuform machine will use model to make multiple molds to be used in production

- Reinforce molds with fiberglass prior to pouring UHPNC

- Fabricate custom design elements (Doors, sinks, bathtub, tiles, counters, etc) for room interiors, and panels or roof tile for building façade and exterior

Note: This department capable of working in congruence with sub-sections of shipping container modification sections (some custom elements will be built around or assembled using plumbing and electrical components). Components can be transferred from respective sub-section as necessary to complete maximum of assembly before being sent to the ‘Main Area’ to be installed.

Custom UHPNC Design Elements

UHPNC Production Capability:

- Equipment in the Non-Structural Architectural Design Element Department of our manufacturing facility can produce 3 yd3 every 10 minutes

- With the consideration of machinery cleaning and form preparation, we expect production capability upwards of 250 yd3 of UHPNC per day

Decatur Building UHPNC Requirements:

- Showers/tubs (5.4 ft3 each)

o 140 units = 28 yd3 - Sinks (0.9 ft3 each)

o 300 units = 10 yd3 - Doors (4.0 ft3 each)

o 170 units = 26 yd3 - Floor tiles (½” thickness)

o 137,000 ft2 = 215 yd3 - Counters (1” thickness)

o 5,400 ft2 = 17 yd3 - Outdoor panels (¾” thickness)

o 12000 ft2 = 28 yd3

Total Required Volume = 324 yd3

Avg Volume/ Container = 0.85 yd3

With an average required production rate of 0.85 yd3 of UHPNC per container, and manufacturing strategy designed for 40 container work orders each day, we can produce 33 yd3 of UHPNC each day.

UHPNC elements will require time for prototyping, color experimentation, and quality control. The seemingly excessive production capability of 250 yd3 each day assures swift manufacturing of these elements once designs are finalized. The manufacturing facility includes sufficient storage space for curing of UHPNC elements prior to work order installation.

Transportation

Transportation Capabilities:

With the consideration that we are limiting a factory to a 100-mile licensing territory, we determined that a fleet of 3 to 12 trucks will guarantee that a minimum of 40 container deliveries can be completed each day.

Transportation Factors:

- 100 mile radius from factory to worksites

- 0.5 hr min/ delivery + (un)load

- 7 hr max/ delivery + (un)load

- 12 container trucks

Minimum of 41 deliveries/day (all deliveries at 100 miles)

Maximum of 580 deliveries/day (all deliveries within 5 miles)

The fleet of 12 trucks will generally be more than necessary. Our manufacturing facility will plan work orders and deliveries to accommodate the construction schedules of multiple work sites simultaneously throughout the licensing territory. We anticipate 6 to 8 trucks being able to complete all deliveries in a typical work day.

On-Site Construction

The on-site construction teams receive work schedules based on the manufacturing facility timetable. Building foundation will first be constructed based on plans from our in-house civil engineering department.

Effective planning and communication with the manufacturing facility allows the on-site teams to anticipate deliveries of completed container work orders.

A crane operator will mobilize incoming containers to their designated position (like Legos). Welders will complete structural connections. The interior team will finish assembly of insulation and non-structural architectural elements. Finally, a utilities team will complete installation of MEP components.

DECATUR ON-SITE CONSTRUCTION REQUIREMENTS

- Foundation construction (using Doka system)

o 1 month - Crane operation (403 containers)

o 150 hrs - Welding (5ft/ container)

o 400 hrs - insulation assembly

o 1000 hrs - interior element assembly (133 units)

o 930 hrs - MEP utility installation

o 1200 hrs

Total Required On-Site Construction Time

3,680 hrs or 154 days

With a conservative on-site construction average time of 2-3 containers per day, we have the capability of simultaneously completing 5 Decatur-sized projects in roughly one year.

Prioritizing development projects and increasing manpower on work sites can complete a single Decatur-sized project at expedited rates.

Manufacturing Production Summary

- Reinforcement production total duration: 1,200 hrs or 53 days

- Electrical production total duration: 600 hrs or 28 days

- Plumbing production total duration: 450 hrs or 21 days

- Mechanical production total duration: 450 hrs or 20 days

- UHPCC production total material: 1,550 yd3

- UHPNC production total material: 324 yd3

Transportation total deliveries:

- Minimum of 41 deliveries/day (all deliveries at 100 miles)

- Maximum of 580 deliveries/day (all deliveries within 5 miles)

- On-site construction total duration:

- 3,680 hrs or 154 days

Note: Because all these activities are done simultaneously, the longest task is the actual duration of the project.