Our Company

Glogreen global started as an innovative R&D design-build company creating disruptive technologies small project at the time. We were positioned to maximize sustainability and optimize efficiencies through every step of the building process, from schematic design to engineering and construction.

In 16 years, We have created a new and unique system of building residential, commercial and industrial structures, all LEED Platinum certified (international green certification). Implementing our own sustainability solutions from conceptual planning to construction, Glogreen limits the risks and maximizes rewards through every stage of development. We bring the best knowledge and technology to build contemporary innovative structures at disruptive prices anywhere in the world. We have created a licensed-based business model, offering a factory to real-estate developers worldwide.

The Strategy is to eliminate all middle men between the developer and the real estate buildings. The Factory is The contractor, engineer and architect working directly for the developers.

The design and building philosophy is to use the maximum of real (free) passive energy throughout the building process by understanding the local environment and be able to implement any new science or technology that brings a solution to our core Expectations :

Help Earth, People and Economy

Building Technique

It important to understand that those techniques and materials are not definitives, but mostly a perfect starting point to reach our goal. Each Factory will adapt based on new sciences and technologies, locals or global needs.

The Framework

Over 700,000 containers currently sit in shipping yards and other storage facilities in the Los Angeles area alone. This costs freight companies millions of dollars due to their lack of recycling solutions and excess storage. We have seized this tremendous opportunity to utilize the structural strength and stability these unique containers provide. They are considered “the strongest boxes in the world” which can resist typhoons, tornadoes, hurricanes and even earthquakes. Making them the ideal material to build the frames of our buildings. Glogreen addresses a major unmet need by utilizing the ISO shipping container with minimal or maximal modifications; the steel of those boxes is important, not their shape.

In our study project, we required 403 shipping containers for the design of a 133 one bedroom extended stay hotel. The goal of this project was to be able to have all the legal certifications and permits for all our materials and calculations.

The Substructure

Another innovative and unique aspect of our construction is what’s between container components. The substructure of our building and internal partition is composed of a proprietary cellulose concrete made up 60% of recycle paper(UHPCC). We create this with blocks of various thicknesses which we build interior walls and partitions with.

This system provides a significant thermal insulation with the highest R-value of R-79 and extraordinary fire resistance.

The Elements

All of the non-structural architectural design elements (bathtubs, sinks, tiles, doors, countertops, roofs, wall panels, etc.) are made with our Ultra High-Performance Nano-Concrete (UHPNC). All of these elements are custom and designed with minimum waste, using local material.

Dexterous Engineering

One of the prominent features in our construction technique is using building blocks that are stronger, more reliable, less costly, and easy to implement, assemble, and prefabricate internally. The shipping containers used as our structure are customized in the production facility according to the building design and then shipped off to the project site to be fastened together.

To do this, we resolve three problems that come with the construction of shipping containers. First, we decompose the structural aspects of a shipping container inch by inch. This allows us to know exactly how much structure we need to reinforce the design we want. Therefore, there are no limitations in size, height and design of the building. Second problem is the shipping container size. The height of a HQ container is 9.5 ft. high, which is a comfortable height of ceiling for living. To not compromise this height, we put all utilities inside the vertical walls. Thirdly, to resolve the insulation problem of containers, we have a proprietary wall assembly made up of our papercrete (UHPCC and a ceramic paint created by NASA.)

Aesthetics

A typical depiction of a shipping container construction is the grungy image of the container’s corrugated panels. However, Glogreen provides an exterior and interior finish that eliminates the visual of the unappealing metal look. The exterior finish is our UHPNC that is waterproof, hurricane and earthquake resistant and provides an extra thermal blanket in addition to our interior cellulose insulation.

Our goal is to be the best of both worlds between manufacturing and on-site construction. This hybrid building process allows us to have no constraints on design and no limitations in manufacturing, while having complete control of costs.

Innovative Technology

At Glogreen, automation and optimization are very important to us. All our system functions cohesively and responsively based on the current and local environment, allowing building components to work as a single entity to efficiently meet all the requirements (Costs, design and time). Using our innovative technology, along with other best-of-class construction technologies, we achieve superior efficiency and sustainability through the following systems:

- CPV (concentrated photovoltaic) Solar technology (30% more efficient) include in the construction costs

- Harvested rain water and recycled grey waters

- ERV (Energy Recovery Ventilation) combined with a patented cooling & heating system that requires a fraction of the energy of a conventional system

- An insulation that require ¼ of the energy to function (R79)

- Solar water heater

- Landscape and green roofs with water efficiency using drip irrigation from grey water source

- Proprietary building material and integrated solution for recycle waste reduce carbon footprint

- Complete automation to create a “smart house” using sensors for thermal comfort, outdoor irrigation, indoor water-use, appliances, automated window shades, etc. along with a total control of the non- visible machinery that makes our buildings work like a Swiss watch.

Manufacturing Process

Our manufacturer is divided in three physical processes.

- The first building will house the cellulose concrete

(UHPCC) process. Capable of making 5000 blocks per day - The second is the structural and physical adaption of shipping containers. Four robots will cut, weld, add any reinforcement the engineers have calculated project by project.

It is also the place where the utilities are installed - The third is an automated system of custom mould making that will produce every interior or exterior architectural elements (tile, countertop, tub, doors, wall panels…) with the UHPNC

UHPCC

PROCESS

↓

ADAPTATION

OF SHIPPING

CONTAINERS

↓

UHPNC/UHPIC

ELEMENTS

Architectural

Autodesk-Revit: Green Building Studio

By using advanced 4D technology we are able to reach the highest levels of control and precision, for a better future in sustainable design. These advanced methods never once thought possible are now a reality with BIM (Building Information Modeling). Harnessing this power will reduce the time of construction, the cost, and the overall waste produced.

Thermal Properties

Structural Analysis

Our structural philosophy of using shipping containers is to meticulously analyze every component and member of the container using one of the top structural software programs, STAAD Pro. This allows us to understand the exact amount of reinforcement needed to reconfigure altered sections for our building design.

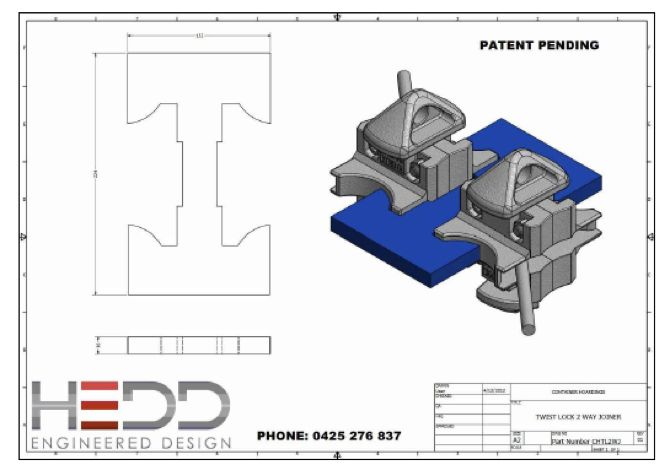

Connection Design

Instead of using the method of welding for the connection between containers, we are using an alternate method of twist locks; similar to those used in securing containers on freight ships. This allows us to save on labor cost, increase precision, expedite installation and increase earthquake resistance.

Foundation Design

Selection criteria for foundation for buildings depend on two factors:

- Soil conditions

- Structural loads

Our building site is located on a firm ground and the soil close to the surface is capable of supporting structural loads so shallow and continuous foundation was selected.

Electrical

This building is able to achieve ¼ of the electrical consumption of an average building same size in Las Vegas.

This is achieved by:

- Innovative HVAC efficient solution

- Innovative Insulative Materials

- Natural Lighting

- Low Voltage Lighting System

- Energy Efficient Appliances

- Building Automation

- Solar Water Heater

The building will utilize solar energy using CPV (concentrated photovoltaic) technology - CPV provides 470,000 kwh/year.

- Battery technology will provide 12 hours of power

- Mitigates use of the grid

Mechanical

ERV (Energy Recovery Ventilation)

Utilizes the energy of the air already inside of the building to cool or heat the fresh air coming in from outside

–Specified to cool outdoor air at 110F down to mid-70s

Plumbing

100% Oxygen-Proof

The Henco multilayer pipe consists of a continuous butt-welded aluminium pipe provided with an inner and outer layer of electron beam cross-linked polyethylene: PE-Xc. Unlike standard synthetic pipes, the aluminium layer of our multilayer pipe prevents the penetration of oxygen. This means that likelihood of corrosion problems is reduced. Additionally, this system is earthquake resistant.

Shape-Retaining

After bending, the pipe retains its required shape. It has no thermal memory and therefore will not spring back when trying to install. This simplifies and accelerates the installation of our pipe.

Gray Water Recycling System

By capturing greywater (showers, sinks, laundry, etc.), and other sources such as rainwater, we can supply all the water for a building’s black water flushing, irrigation and other uses.

This addresses water scarcity issues and sets us up to achieve LEED Platinum. Decatur requires 8,000 gallons per day to function. Thanks to this system, we can reuse 5,000 gallons; 4,000 into black water and 1,000 for the landscape.

Evacuated Tube Solar Collector System

(Domestic Hot Water)

Solar Hot Water Heater

- Originally developed in the 1980’s, these collectors are capable of absorbing sunlight and converting it to usable heat

- Each evacuated tube can provide over 60 Watts/204 Btu of water heating output

- We have created a hybrid system using the sun and then adding the energy needed to reach the desired water temperature

Unisciti alla rivoluzione RhIZO

Stiamo cercando 250 persone per partecipare alla prevendita di FCO a un massimo di 2000 dollari.